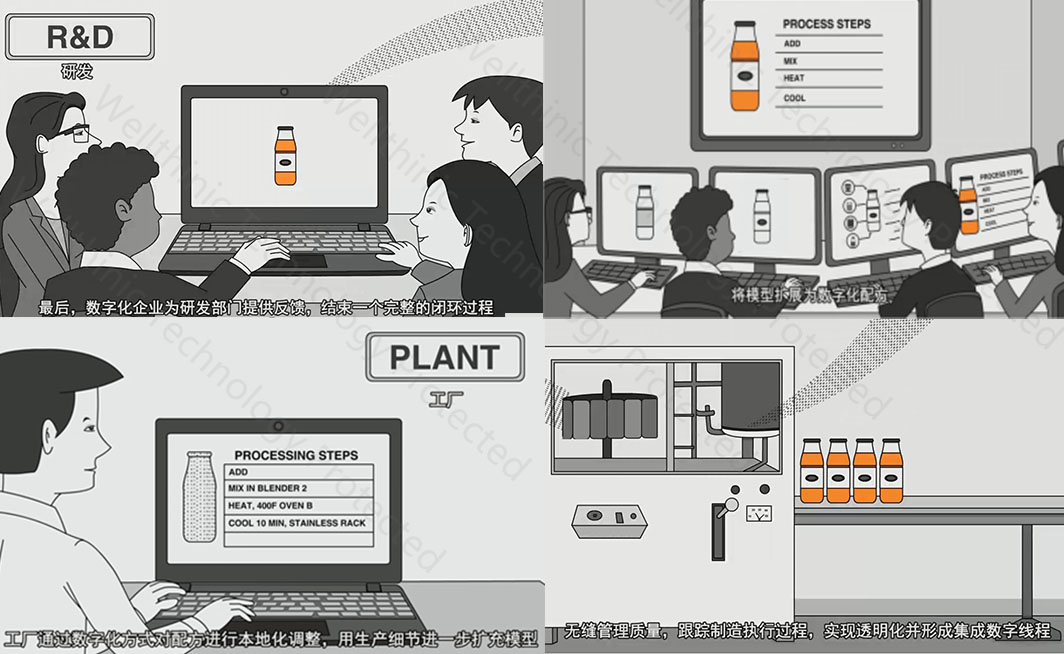

The RD for Product Research and Development management system can leverage its R&D potential to develop new products effectively. It simplifies and optimizes all product development processes and aligns them with manufacturing. This ensures that product designs and processes always meet quality and regulatory requirements. By smoothly integrating and ensuring the consistency of R&D and manufacturing data and processes, it can significantly accelerate the delivery of final product designs to mainstream manufacturing.

In the face of a wide variety of product R&D, complex processes, and poor traceability with only paper-based document management, the system can address industry pain points through functions such as product specification management, formula workbench, and electronic batch record books. It improves the efficiency of product R & D, reduces unnecessary R&D work, provides convenient information-based services for product R & D, and speeds up the product launch process.

Leverage the RD product R&D management system to meet the transformation and construction needs of the batch process industry and speed up the product launch process.

【The RD system can simplify, optimize, and adjust the R&D of formulated products, improve the innovation efficiency of Consumer Product Goods, and optimize CPG data management.】

Features

• Maintain a single source of data

A single repository maintains current detailed information about all raw materials, semi-finished products, finished products, and packaging materials. This improves the search efficiency of R&D activities and enhances confidence in the real-time nature and accuracy of the data.

• Create a digital twin of the formula

The data information of product formulas and specifications is stored in a single data repository, enabling product innovators to evaluate and optimize business processes and the compliance management of data before entering the testing phase of formulated product development.

• Securely store data in electronic laboratory notebooks

It supports the electronic management of project related data within the notebook structure, offering a high degree of flexibility and searchability while ensuring strict data security for all CPG product development activities.

• Ensure compliance with GMP

The system monitors production sampling and testing to ensure compliance with current Good Manufacturing Practice, meeting the requirements of retail customers and regulatory authorities.

• Enable compliant labeling

Using the Bill of Materials (BOM) and all specification details, the system can automatically summarize ingredients, nutrition, allergens, and other required information to ensure that labels comply with regulatory requirements.

• Create integrated reports

The system automatically generates all necessary reports, including trends and charts related to laboratory and product quality, based on specification verification results.

Business Benefits

• Advanced integrated components

Electronic laboratory notebook templates, laboratory management, specification management, product compliance, and support for intellectual property processes.

• Formula workbench

Simplify the product development process, align it with manufacturing, and ensure that designs and processes meet quality and regulatory requirements.

• Accelerate product R&D

Ensure consistency between R&D, data, and processes to speed up the delivery of product designs to mainstream manufacturing.

• Improve production quality

Form a quality closed-loop from in-factory to out-of-factory through seamlessly - cooperating integrated laboratory management components.

• Reduce complexity

Utilize a unified specification management repository across the entire enterprise to provide access and version control for all R&D activities.

External links:https://plm.sw.siemens.com

Address: Room 3134, 3rd Floor, No. 158 Liyi Road, Xiaoshan District, Hangzhou, Zhejiang Province 311215, P. R. China

Address: 3rd Floor, Building T6, No. 308 Kangshan Road, Pudong District, Shanghai, 201315, P.R.China

Address: 11th Floor, No. 18 Zhihui Road, Huishan District, Wuxi, Jiangsu Province 214174, P. R. China