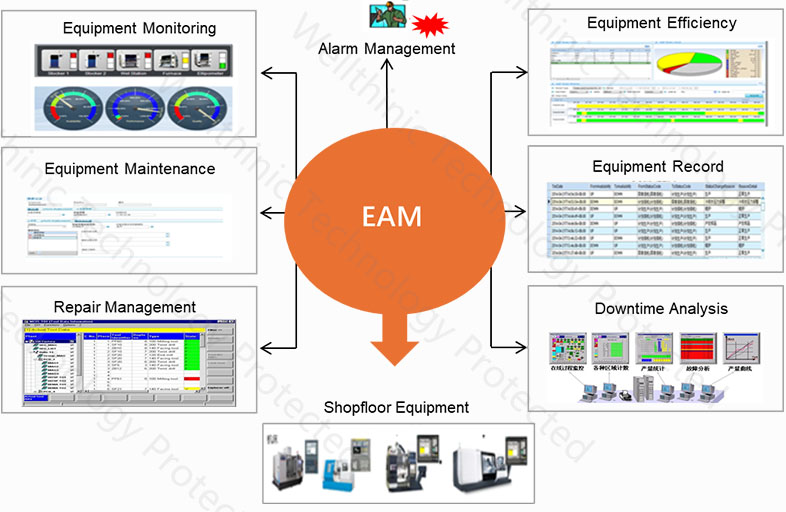

Provide effective management and monitoring of the entire life cycle of equipment through integrated management means, improve the utilization rate and stability of equipment, and reduce the quality risks caused by equipment factors. Starting from multiple aspects such as the standardized use of equipment, regular maintenance, the integration of IT and OT, and data-driven analysis and improvement, keep the equipment in good condition at all times, enabling it to execute production efficiently and with high quality, and avoid the equipment from becoming a production bottleneck that causes efficiency and quality losses.

Features

• Digital management of the entire life cycle

Carry out standardized management of the whole process from equipment procurement and acceptance, use and maintenance to scrapping, ensure the integrity of data, reduce the risk of default, and provide comprehensive support for equipment management.

• Real-time monitoring and early warning

Collect equipment operation data in real time, such as temperature, pressure, etc., and evaluate the equipment status through data analysis. When an abnormality occurs or the maintenance threshold is reached, an early warning will be automatically triggered, and relevant personnel will be notified by means of sound, images, etc., to ensure the safe operation of the equipment.

• Efficient maintenance and repair management

Generate maintenance tasks and remind maintenance personnel to perform their duties on time. Respond quickly when a fault occurs, record the fault information in detail and analyze the cause, reduce the fault occurrence rate, and improve the reliability of the equipment.

• Precise management of spare parts

Link maintenance and repair operations with spare parts, automatically trigger the consumption of spare parts, track key spare parts, avoid shortages of spare parts, and improve the timeliness of equipment repair.

Business Benefits

• Improve equipment operation efficiency

Through real-time monitoring, regular maintenance, and timely repair, reduce the downtime of equipment due to faults, improve the utilization rate and stability of equipment, ensure production continuity, and enhance the overall production efficiency.

• Reduce operating costs

Precise management of spare parts reduces inventory backlogs and waste, and a reasonable equipment maintenance plan reduces maintenance costs. Centralized or distributed deployment optimizes resource allocation, reduces hardware investment, and lowers the operating costs of enterprises.

• Improve management efficiency

Realize the informatization and standardization of equipment management, reduce the cumbersome work of manual management, and improve management efficiency. The on-site inspection management on mobile devices is convenient for on-site operation, and improves the timeliness and accuracy of equipment management.

Address: Room 3134, 3rd Floor, No. 158 Liyi Road, Xiaoshan District, Hangzhou, Zhejiang Province 311215, P. R. China

Address: 3rd Floor, Building T6, No. 308 Kangshan Road, Pudong District, Shanghai, 201315, P.R.China

Address: 11th Floor, No. 18 Zhihui Road, Huishan District, Wuxi, Jiangsu Province 214174, P. R. China