The integration of DCS (Distributed Control System) and Batch systems serves as the standard solution for recipe-driven production in process industries, particularly suitable for industries requiring batch control such as pharmaceuticals, food and beverage, and fine chemicals.

Application Area

Pharmaceuticals: Blood Products, Chemical Pharmaceuticals, Cell Therapy, Gene Therapy, Antibody Products, Vaccine, Traditional Chinese Medicine

Chemicals: Flavors & Fragrances, Catalysts, Adhesives, Lubricants, Coatings & Inks, Electronic Chemicals, New Energy Materials

Food & Beverage: Dairy Products, Infant Formula, Health Products, Liquor, Cosmetics & Personal Care Products, Seasonings, Beer

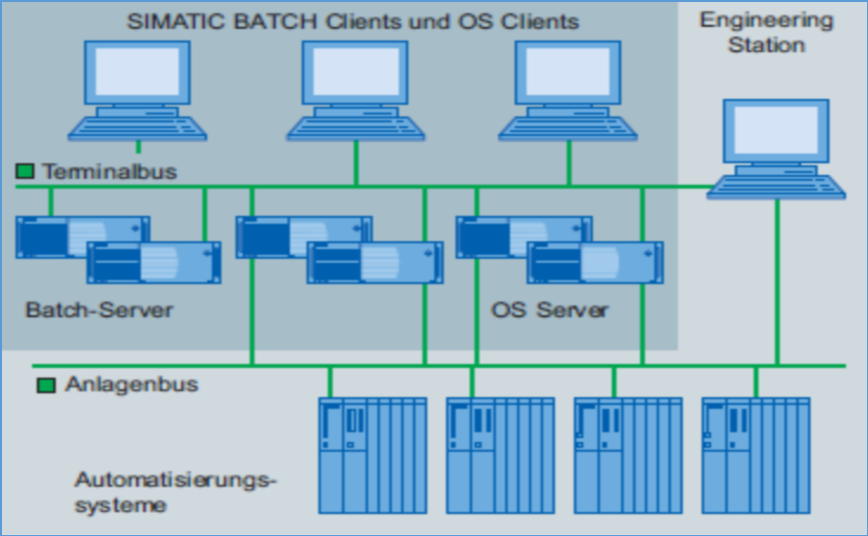

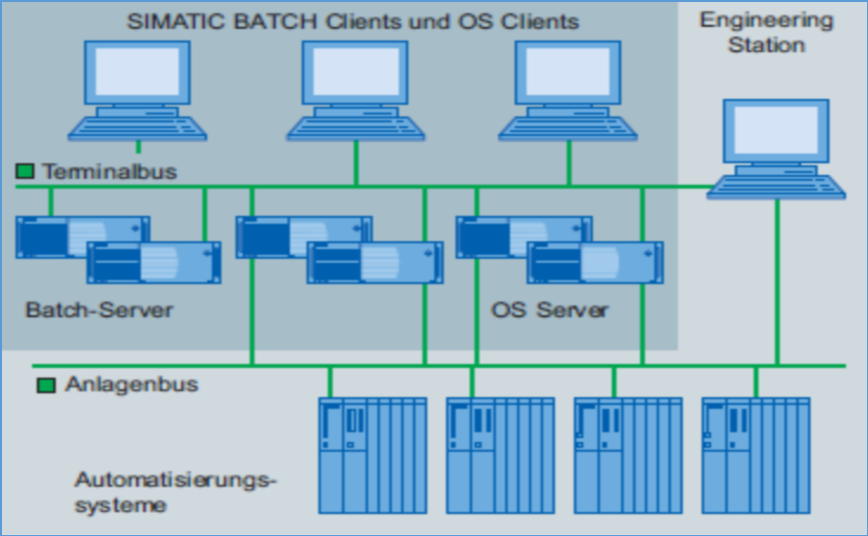

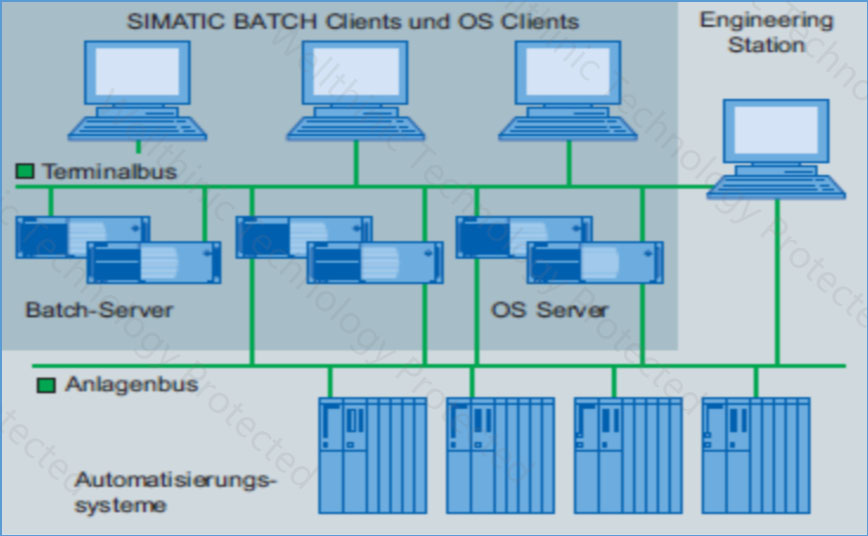

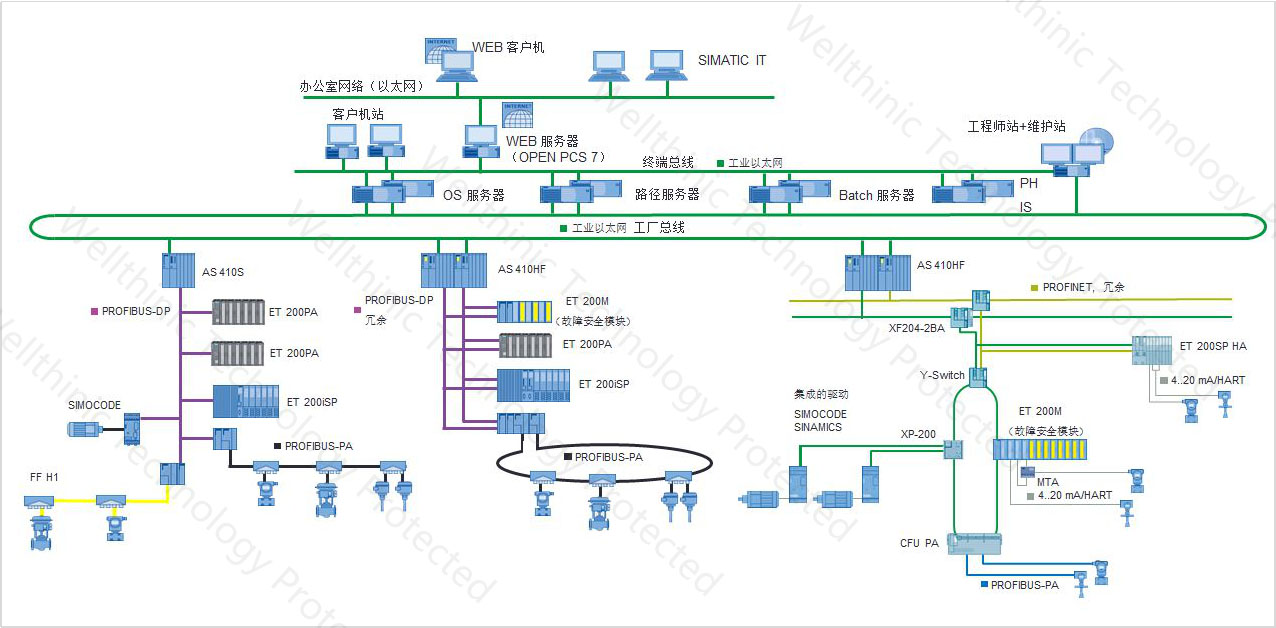

Typical System Architecture

System Function Introduction

The DCS system provides:

Basic continuous control (e.g., PID regulation), equipment-level interlocking, real-time data acquisition, and human-machine interface (HMI).

It supports multiple network protocols: Industry ethernet, profiNET, Profibus-DP, PA bus, ISP bus, TCP/IP, etc.

It supports multiple functions: route control, batch control, process history data server, web server

It supports multiple network structures: line, star, ring or combination structure

The Batch system provides:

Recipe management (master recipes, control recipes),Batch tracking and traceability,Phase logic control (Phase Logic),Production order execution

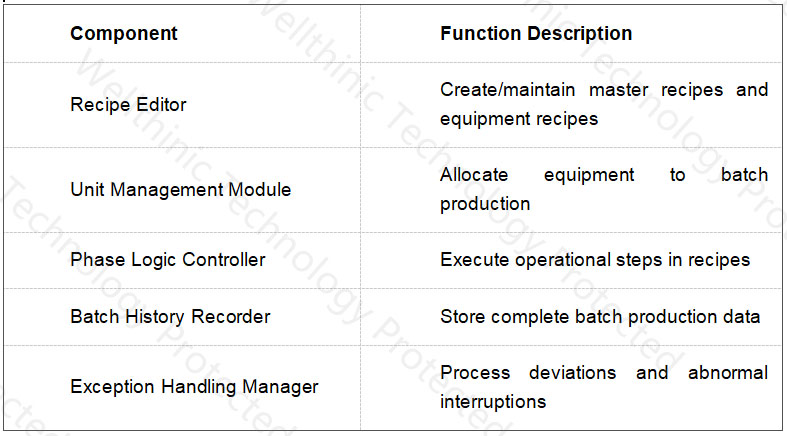

Key Components of SIMATIC Batch

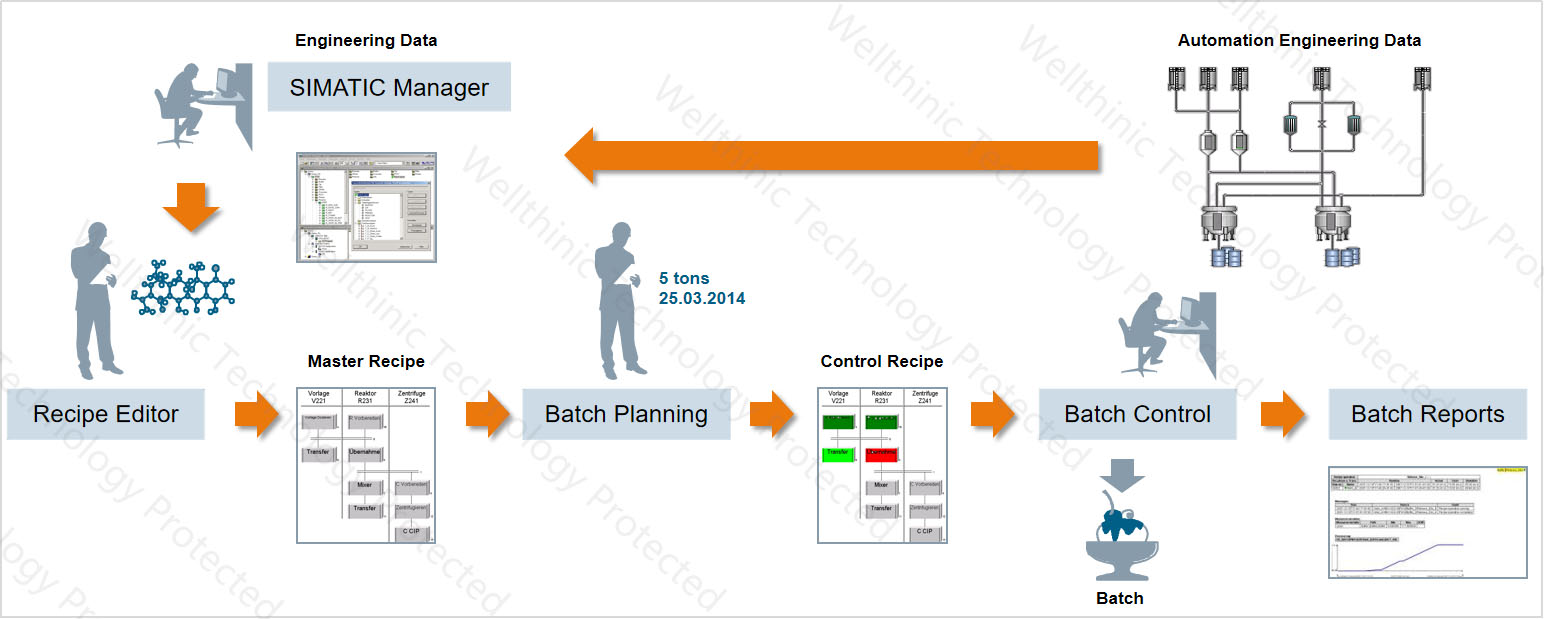

SIMATIC Batch Workflow

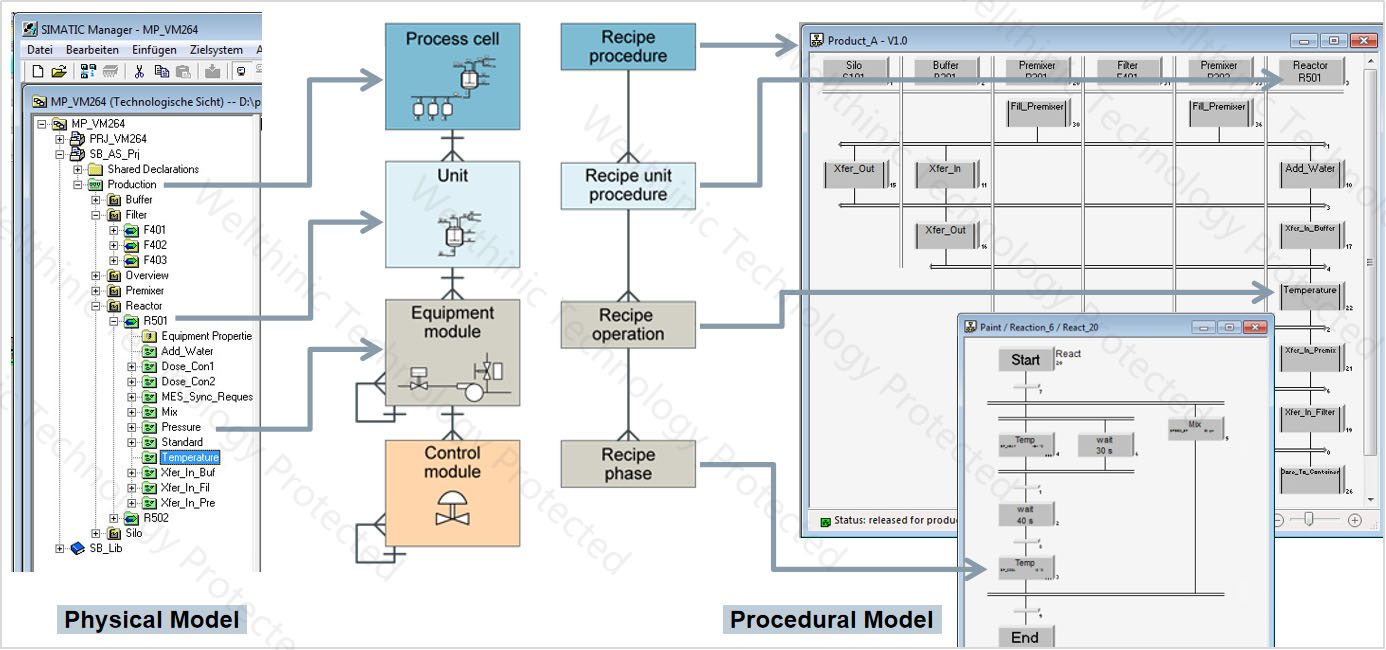

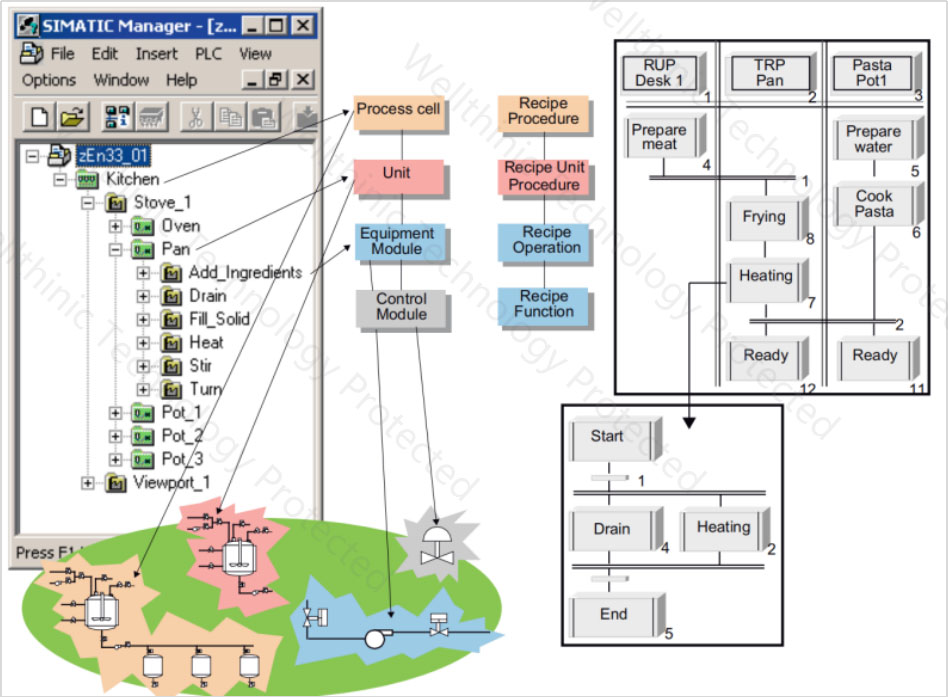

Hierarchical Recipes according ISA-88.0

Uses the physical and procedural models of ISA-88 for the utilization of plant equipment

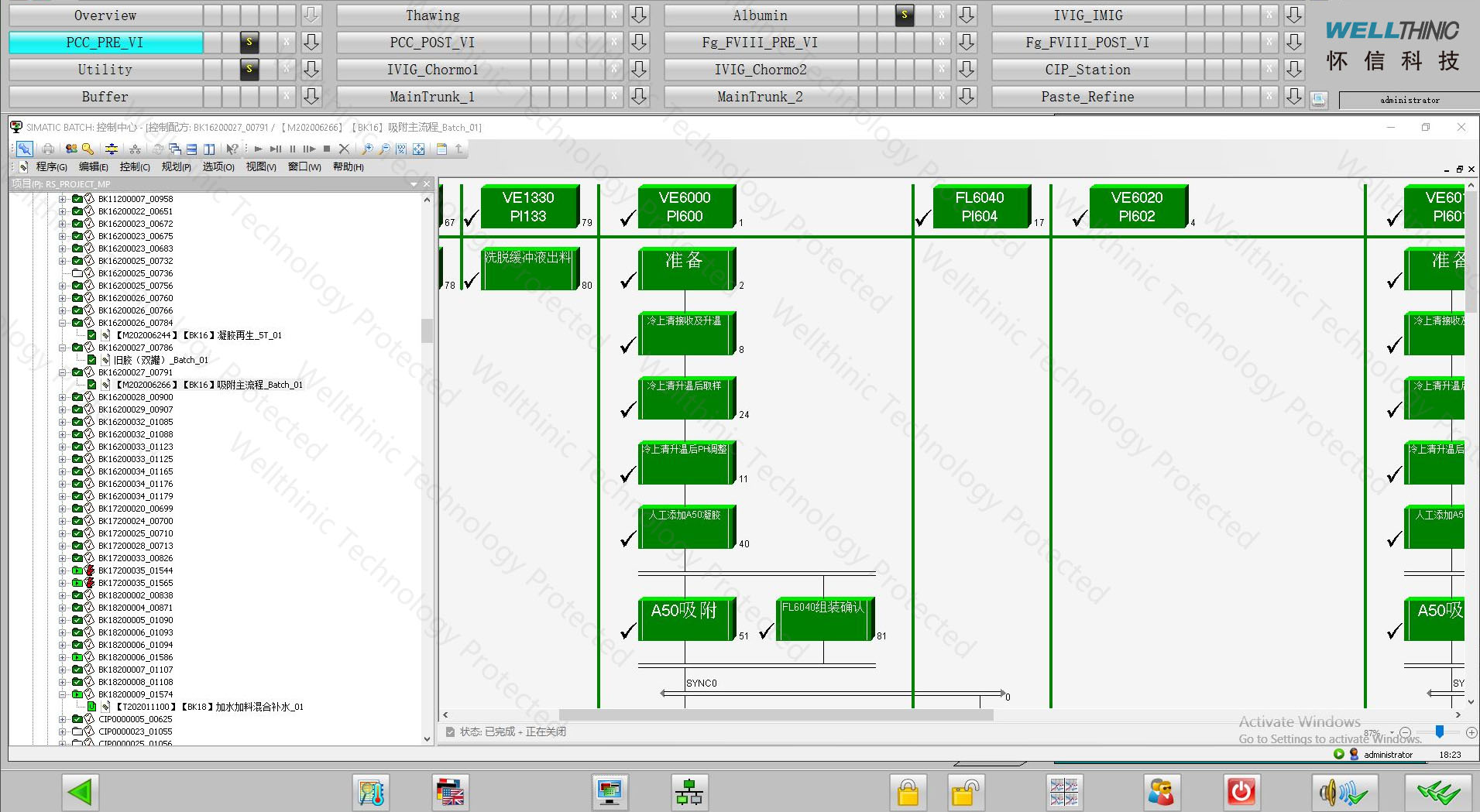

Application Example 1: CFC+SFC+Batch

Hardware : CPU410-5H+ES+OS

Software: Siemens PCS7 + Batch

Benefits:

Flexible configuration and modular architecture

Perfectly integrated with the PCS7 sequential control software SFC to achieve flexible formulation of actions and parameters

Minimize cleaning/preparation time during batch switching

Optimization of the number of parallel batches

Implemented full batch lifecycle management from raw materials to finished products

Simultaneously maintaining the precise control capability of DCS over underlying equipment

It is the core technical solution for achieving flexible production in batch process industry

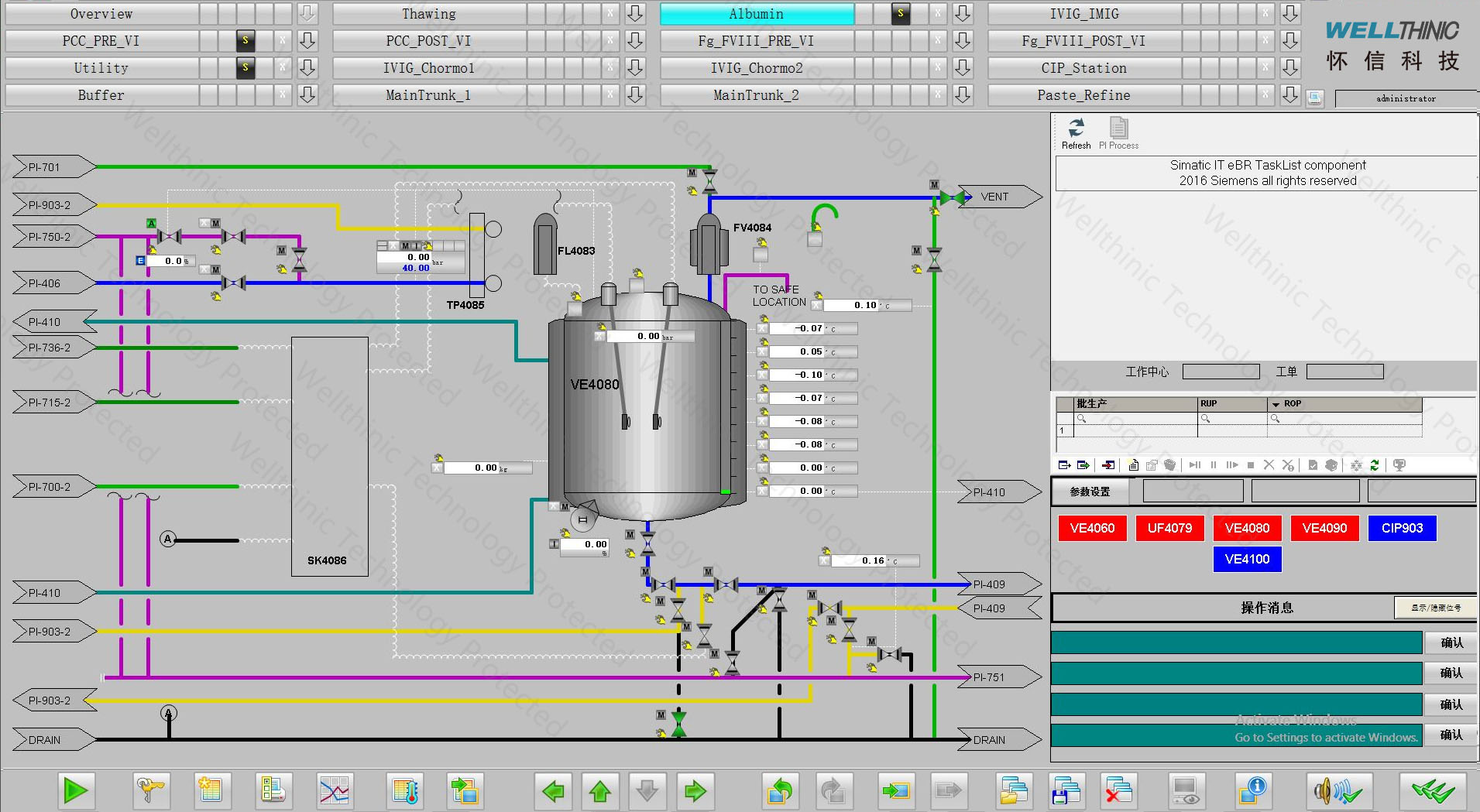

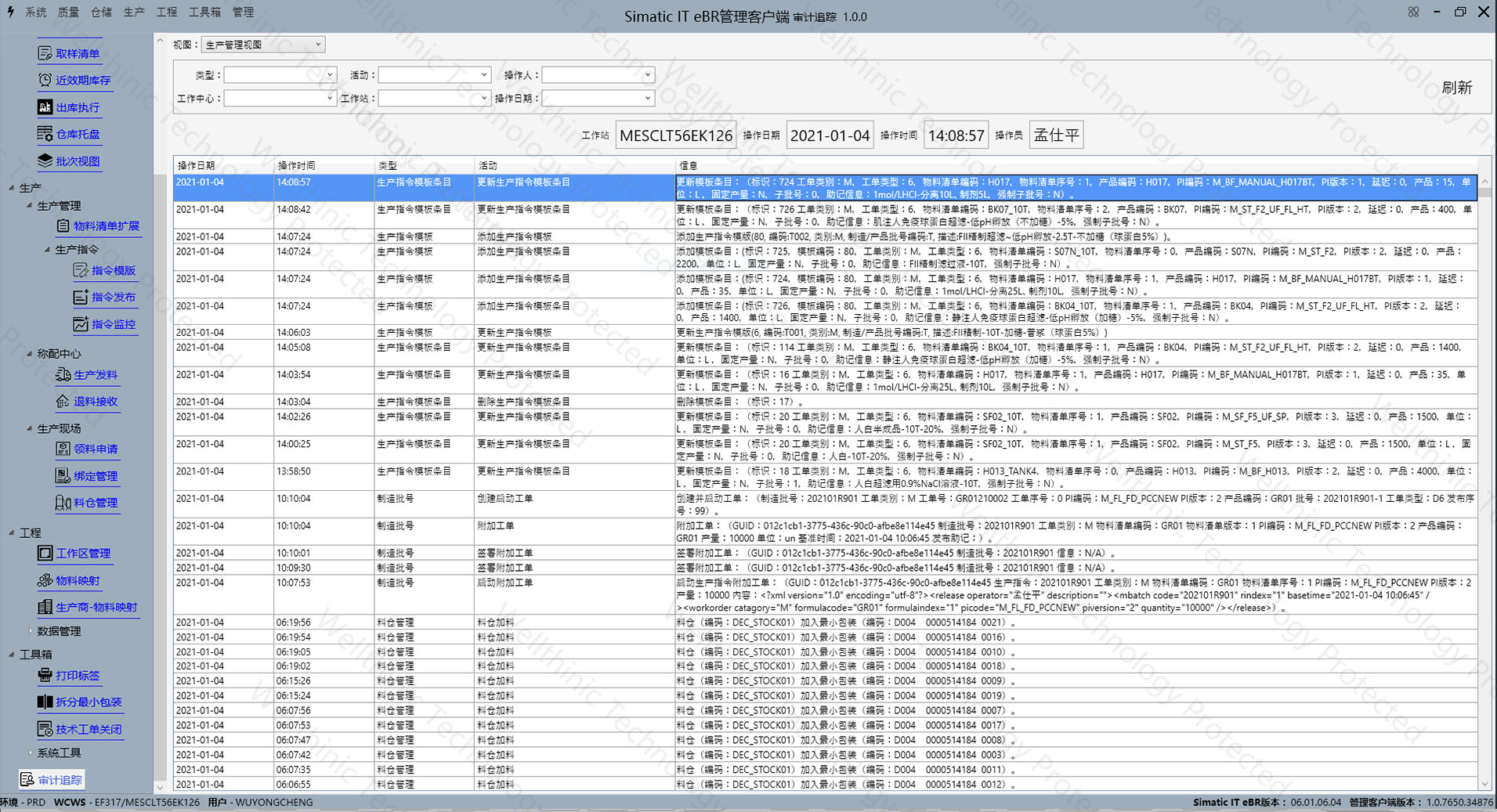

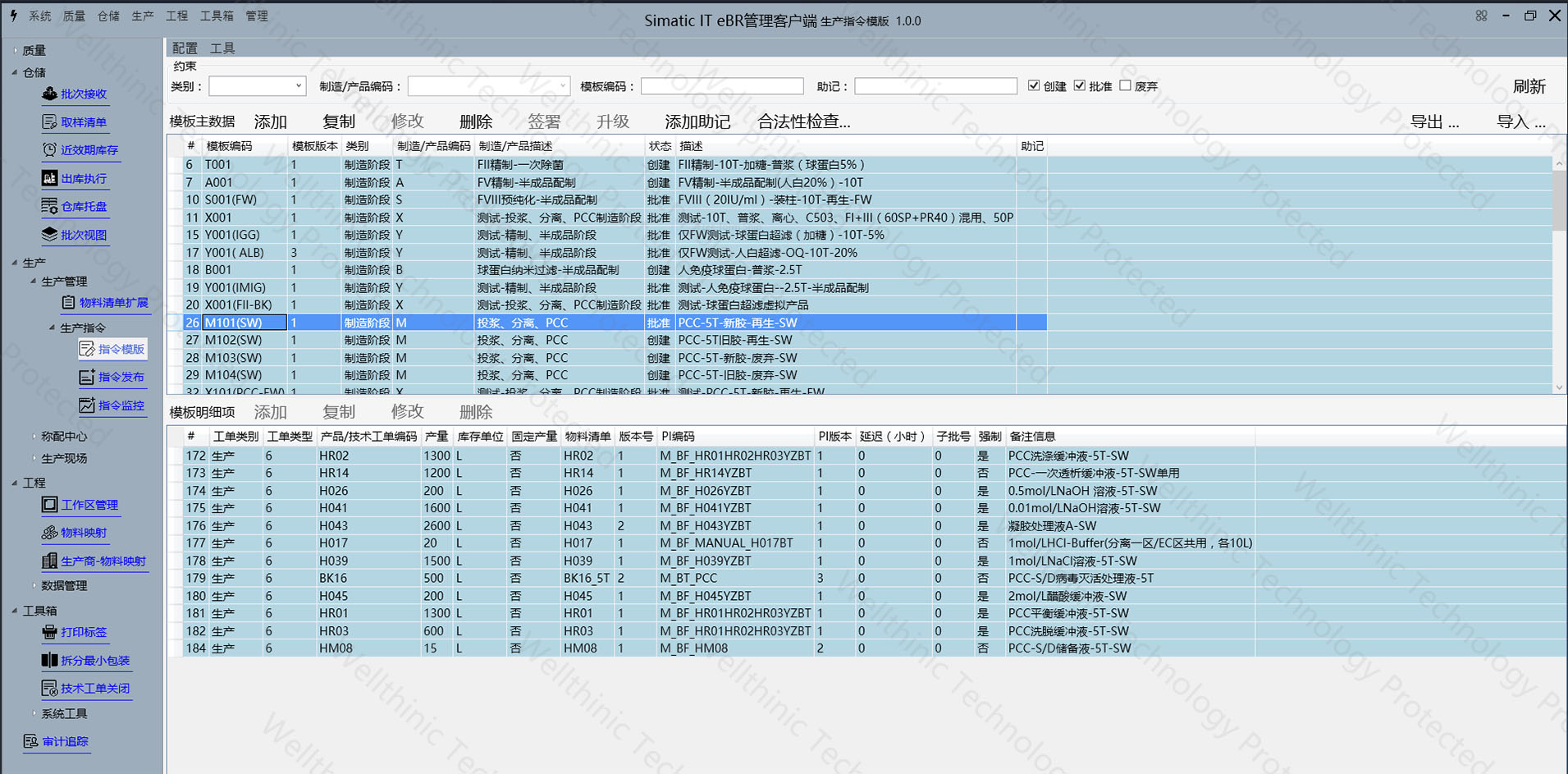

Application Example 2: PCS7+Batch+Audit Trial+SIMATIC IT eBR (Opcenter Execution Pharma)

Manage Audit Trial:

Production order from EBR:

Hardware: CPU410-5H+ET200SP HA

Software: SIMATIC PCS7+Batch+SIMATIC IT EBR (Opcenter Execution Pharma)

Benefits:

Easy creation of recipes through graphical user interface

Easy modifications and adjustments

Enhanced flexibility

Easy connect with higher management network

Address: Room 3134, 3rd Floor, No. 158 Liyi Road, Xiaoshan District, Hangzhou, Zhejiang Province 311215, P. R. China

Address: 3rd Floor, Building T6, No. 308 Kangshan Road, Pudong District, Shanghai, 201315, P.R.China

Address: 11th Floor, No. 18 Zhihui Road, Huishan District, Wuxi, Jiangsu Province 214174, P. R. China