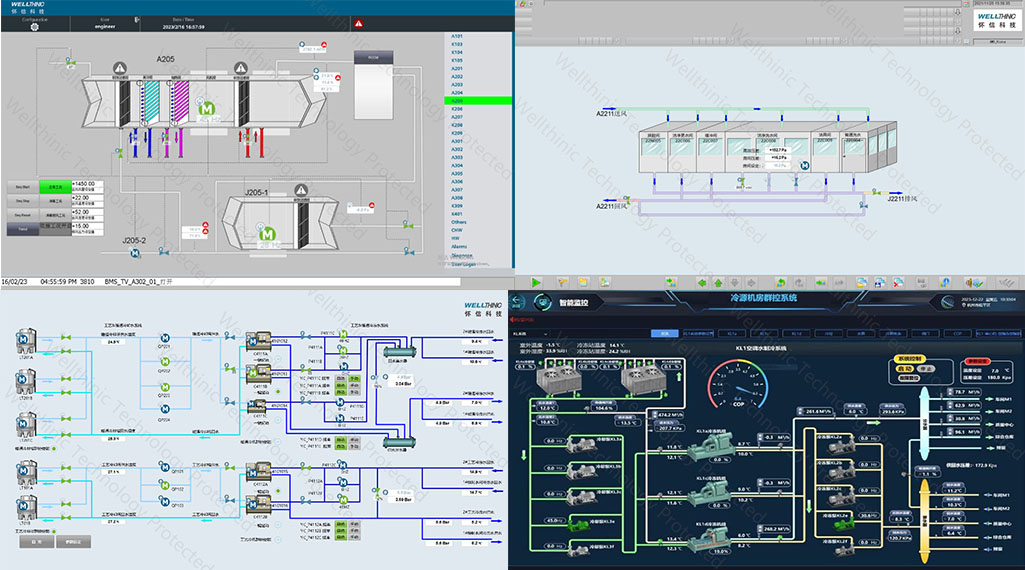

BMS (Building Management System) Centralized monitoring and management of electromechanical equipment within buildings (such as HVAC, lighting, elevators, security systems, fire protection systems, etc.) to optimize energy usage and enhance operational efficiency.

Application Area

GMP Facility, Electronic Clean Production Workshops, Scientific Research Laboratories, Data Centers, and Hospitals, etc.

System Function Introduction

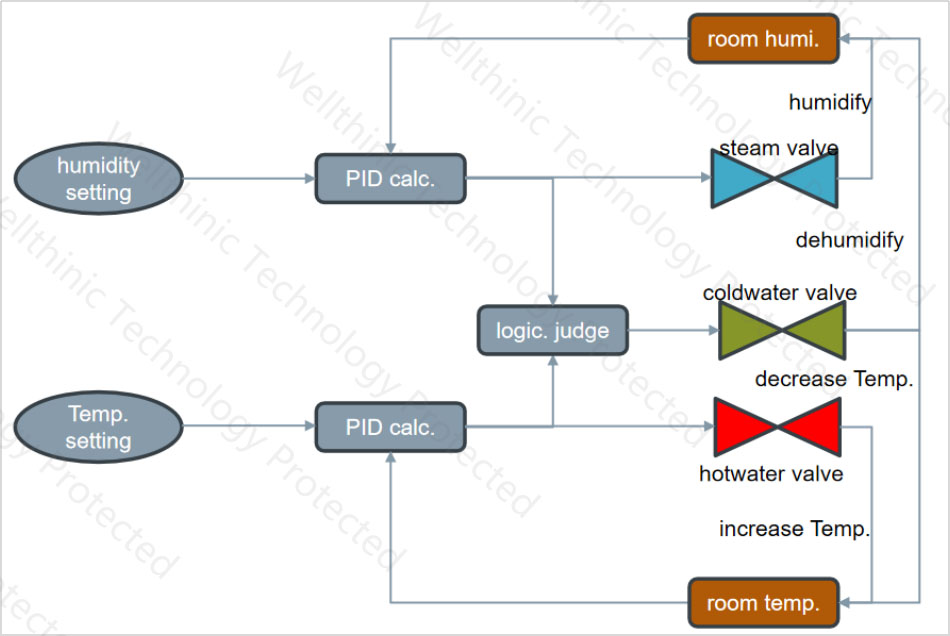

Single Loop Control

The controlled parameter is the room temperature, and the adjustable parameter is the 0-100% output of PID control as the input signal for valve range control. Suitable for small air conditioners or comfort air conditioning units, the advantage is that the valve directly controls the room temperature and humidity, the logic is simple, and the adjustment speed is relatively fast.

Dual Loop Control (temp+temp)

%20.jpg)

The controlled parameter for cascade control is the return air temperature, and the adjusted parameter is the supply air temperature. The set value of the main PID control loop is the system temperature set value, and the detection value is the system return air temperature detection value. The set value of the secondary PID control loop is the output of the main loop, and the detection value is the system supply air temperature. The 0-100% output of the secondary PID control loop is used as the input signal for valve range control, which is suitable for high air volume and multi room clean air conditioning systems; The advantage is stable control, relatively small fluctuations in room temperature and humidity, and less influence of outdoor climate factors.

Dual Loop Control (temp+temp)

%202.jpg)

The controlled parameter for cascade control is the humidity of the return air, and the adjusted parameter is the dew point of the supply air. The set value of the main PID control loop is the system humidity set value, and the detection value is the system return air humidity detection value. The set value of the secondary PID control loop is the output of the main loop, and the detection value is the system supply air dew point. The 0-100% output of the secondary PID control loop is used as the input signal for valve range control, suitable for high air volume and multi room clean air conditioning systems. The advantages are stable control, relatively small fluctuations in room temperature and humidity, and less influence of outdoor climate factors.

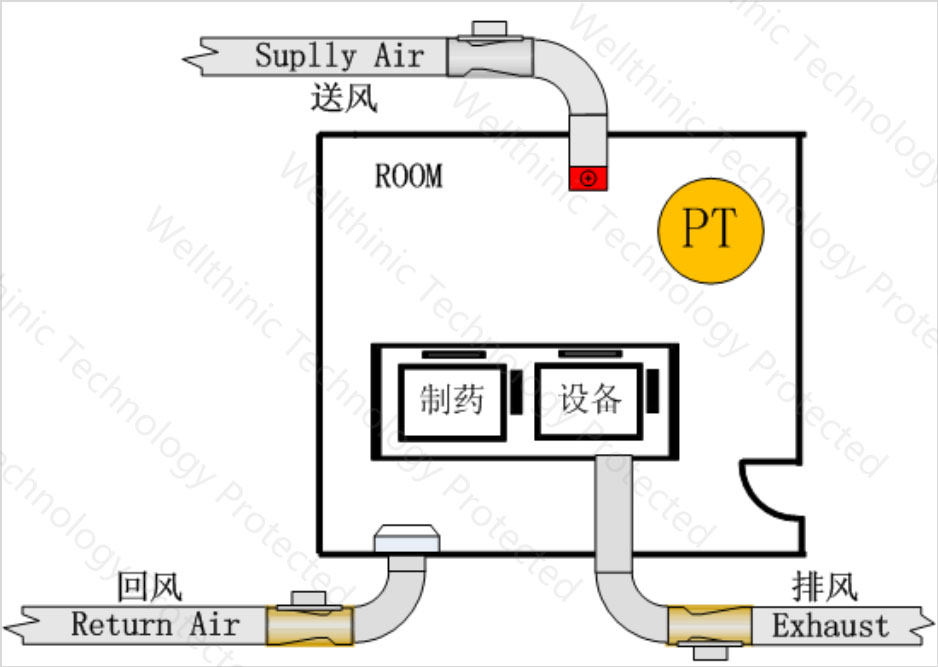

Room Dif-Pressure Control Mode 1

Air balance: residual air volume=fresh air volume + supply air volume - return/exhaust air volume.

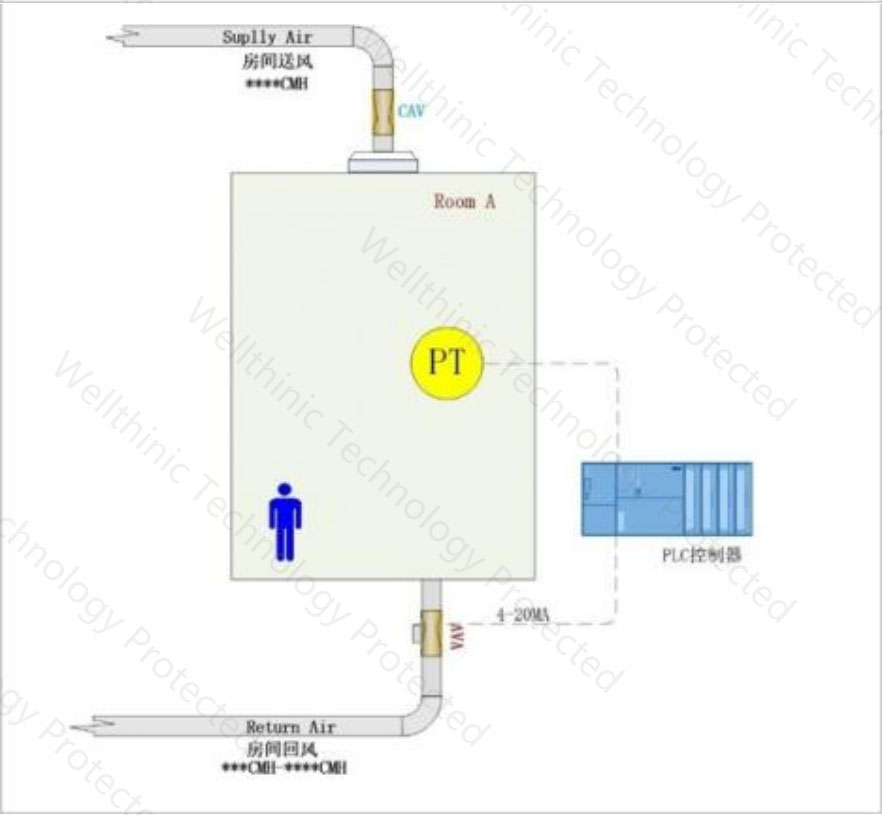

Room Dif-Pressure Control Mode 2

Air balance: supply air volume=return/exhaust air volume + residual air volume.

Main Applications

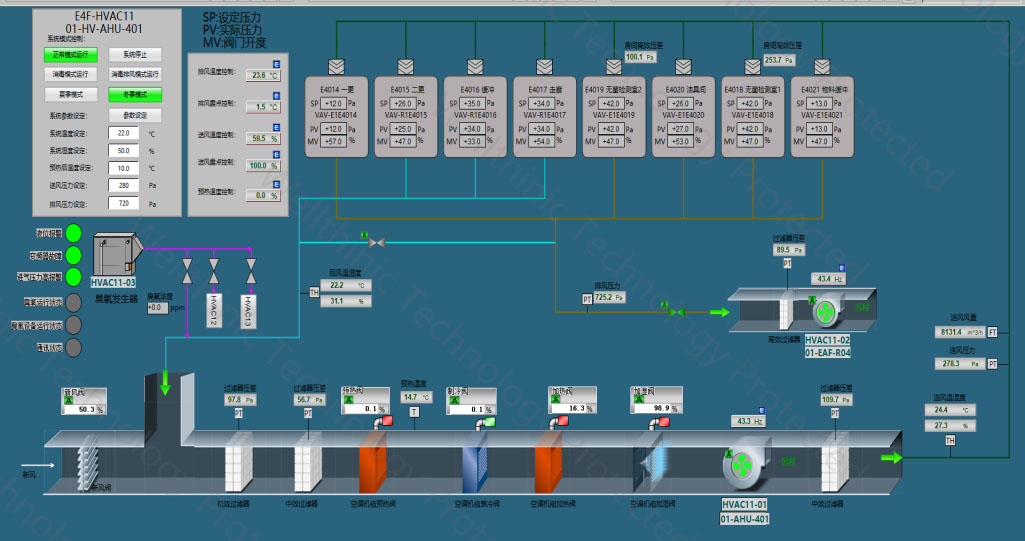

Product Technology: SIMATIC PCS7/TIA+WINCC

Delivered Function:

Temprature control

Humidity control

Dif-Pressure control

Static press. control

Airflow control

Mode Switch:

Working mode

Normal mode

Sterilization mode

Disinfection Exhaust mode

Energy-saving mode/On-duty mode

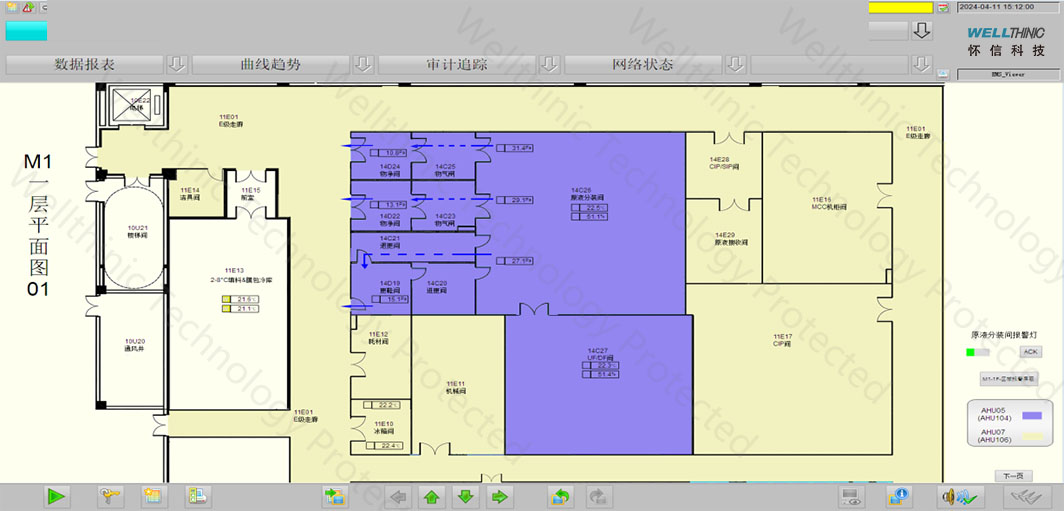

EMS is a monitoring system for the GMP environment, which provides status feedback on the environment controlled by the BMS. When changes occur in the environment that disrupt the GMP-compliant conditions, it generates alarms and records, serving to prompt timely attention and facilitate subsequent traceability, analysis, and improvement of abnormal states.

In pharmaceutical factories, environmental monitoring systems (EMS) play a crucial role, not only in protecting the environment, but also in ensuring the safety and compliance of drug production processes with regulations. Here are some key application scenarios of EMS in pharmaceutical factories:

Production workshop: Monitor the environmental conditions of key production areas, such as sterile production areas

Storage areas: Ensure that drug storage conditions comply with regulations, such as temperature and humidity

Laboratories: Monitor the laboratory environment to ensure the accuracy and reproducibility of experiments

Packaging areas: Maintain suitable environmental conditions to prevent product contamination during the packaging process

Chamber-type equipment: Ensure that equipment and environmental parameters are maintained under appropriate conditions

Main Applications

Product Technology: Siemens CPU410+ET200SP HA+WINCC

Software: PCS7 or TIA

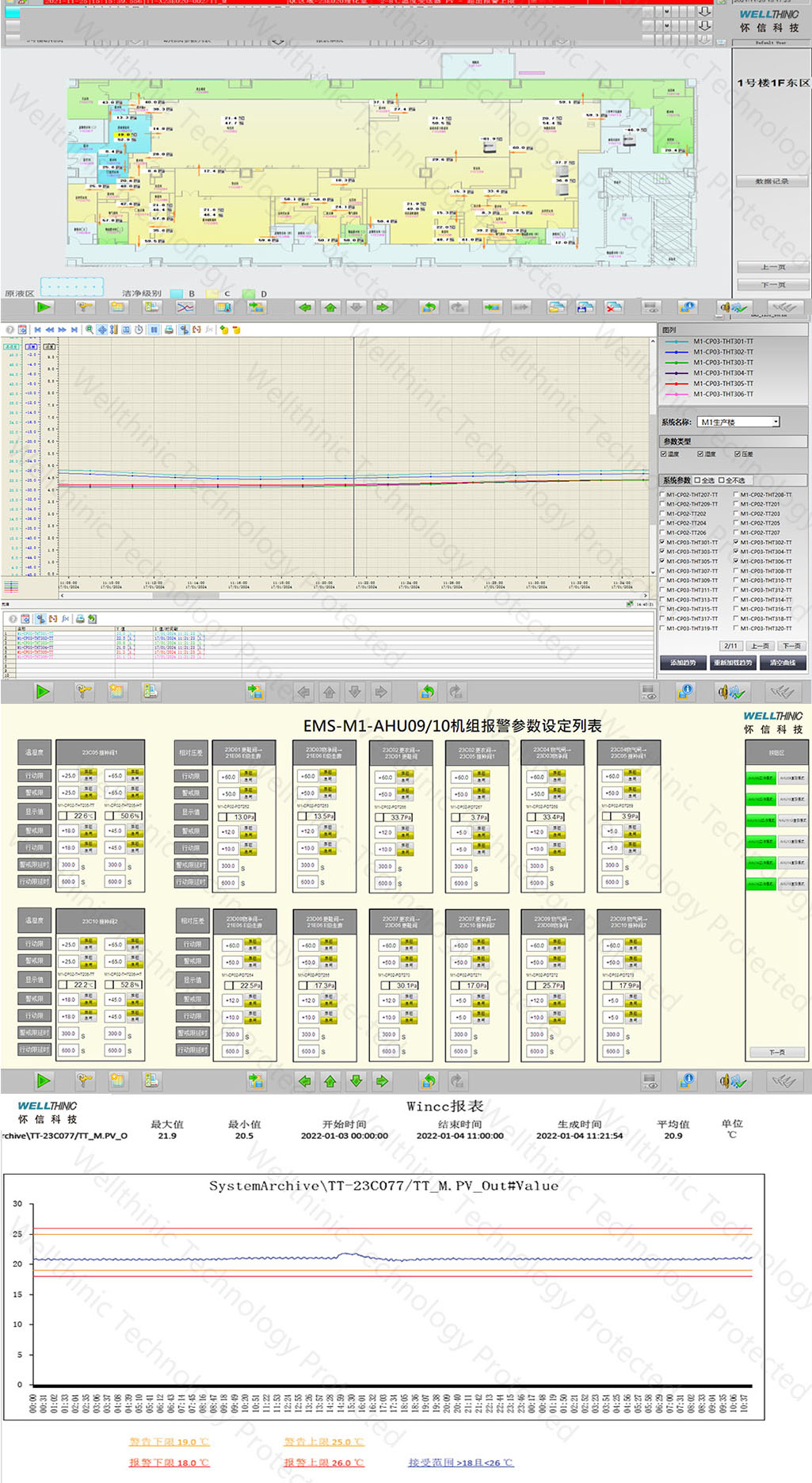

Delivered Function:

1:Real time monitoring and alarm

The EMS system continuously monitors environmental parameters such as temperature, humidity, pressure difference, carbon dioxide, etc.

When these parameters exceed the preset safety or compliance range, the system will automatically trigger an alarm

2:Real time monitoring and alarm

The purpose of an alarm is not only to notify abnormal situations, but also to initiate preventive measures to prevent potential environmental impacts

The system can be configured to automatically adjust or shut down relevant devices when anomalies are detected to reduce risks

3:Data recording and analysis

All alarm events will be recorded and stored for subsequent analysis and review

These data help identify the root cause of the problem and improve environmental management strategies

4:Compliance assurance

In industries that need to comply with specific environmental standards and regulations (such as pharmaceuticals, food processing, healthcare, etc.), the alarm function of the EMS system helps ensure that all operations are carried out within the framework of industry standards

5:Highlight

No false alarm、No omission of records、Controllable、Complete report

Address: Room 3134, 3rd Floor, No. 158 Liyi Road, Xiaoshan District, Hangzhou, Zhejiang Province 311215, P. R. China

Address: 3rd Floor, Building T6, No. 308 Kangshan Road, Pudong District, Shanghai, 201315, P.R.China

Address: 11th Floor, No. 18 Zhihui Road, Huishan District, Wuxi, Jiangsu Province 214174, P. R. China