Industry: Lubricants - MES, EAM, IoT

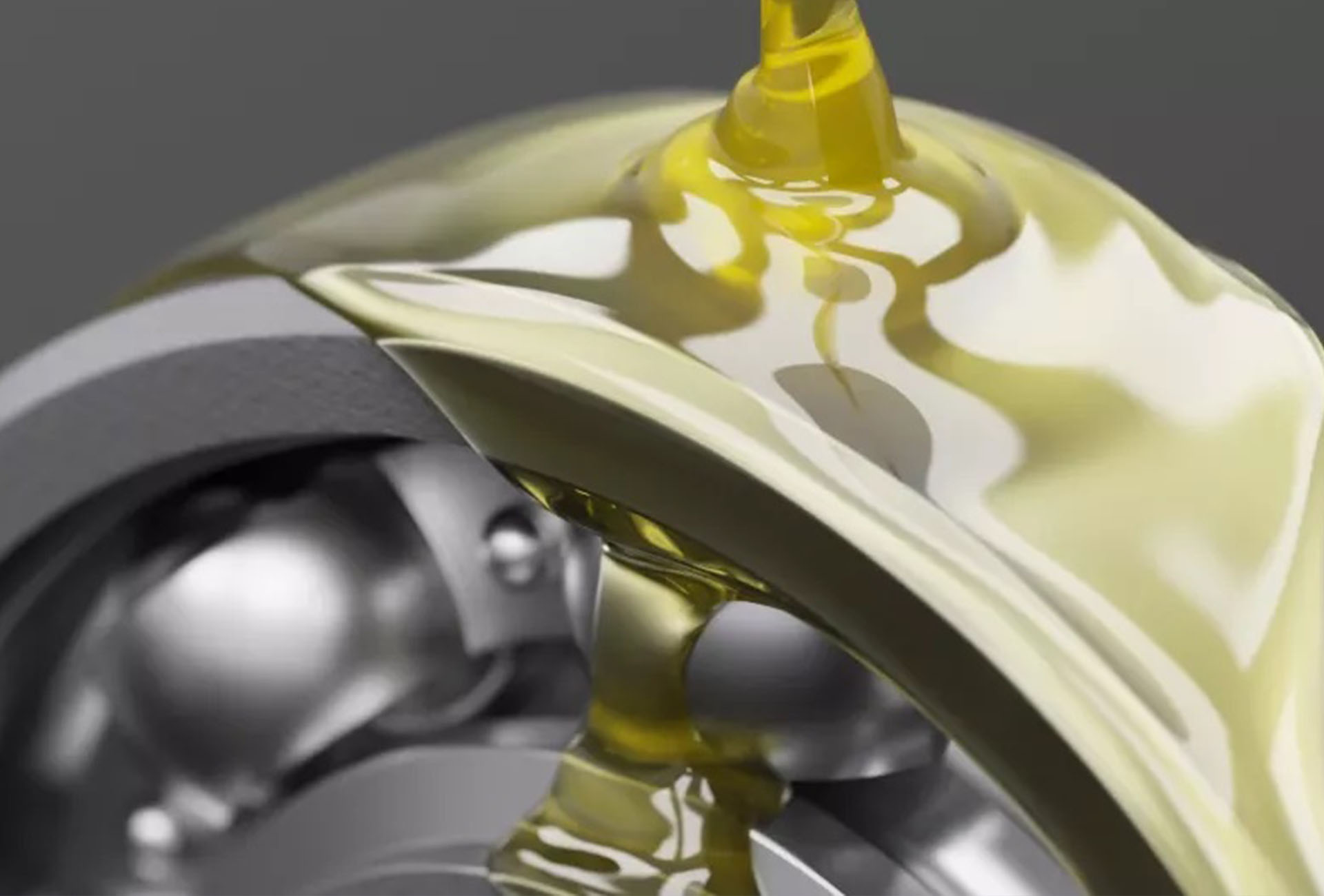

Fuchs Lubricants (China) Co., Ltd. is a leading enterprise in the lubricants field of China's manufacturing industry and one of the earliest international lubricant companies to invest in building factories in China. As the only multinational lubricant R&D headquarters certified by the Shanghai Municipal Government, Fuchs China relies on Germany's cutting-edge technology and high-quality raw materials purchased globally to establish a full-chain intelligent industrial system integrating R&D, production, and testing. Currently, Fuchs China has two modern production bases in Suzhou and Yingkou, equipped with internationally leading intelligent production equipment and digital management systems, creating a benchmark for intelligent manufacturing in the lubricant industry.

Solution Description:

Adopting a standard product solution, it focuses deeply on recipe management, oven management, batch picking, and automated interaction. By real-time monitoring of key parameters such as process execution, temperature, and humidity, it ensures the accuracy and stability of the process and constructs a full-process visualization and traceability system from raw materials to finished products. Deeply integrating various production systems, it automatically synchronizes basic material data, seamlessly cooperates with the automation system, accurately issues work orders, process steps, and parameters, efficiently collects equipment operation data, and optimizes scheduling and monitoring. The solution covers intelligent operations such as special material reminders, powder weighing, feeding error prevention, and weight reduction feeding, integrates packaging equipment, completes the issuance of process parameters and collection of equipment status, comprehensively improves production efficiency, and reduces manual intervention and errors.

Implementation Effect:

Deep integration of multiple systems realizes automatic data interaction, eliminates information silos, reduces human intervention, and improves operational efficiency

Deep integration of IT and OT systems enables the system to directly issue instructions and drive the automated execution of equipment, improving production accuracy

Realizes the automatic material calling function based on actual production needs, optimizes material supply, and reduces the inventory pressure in the shop floor

Automatically generates process guidance according to product formulas to ensure the standardization and standardization of the production process

Formulates weighing rules through the system to accurately guide the use of materials, prevent misusing and underusing, and eliminate quality accidents

Realizes the automation, intelligence, and standardization of the entire production process, improving efficiency, reducing costs, and ensuring quality

Cooperative Projects and History:

2023 - 2024, MES Digital Factory Project of Suzhou Factory

2023 till now, MES Digital Factory Project of Yingkou Factory

Address: Room 3134, 3rd Floor, No. 158 Liyi Road, Xiaoshan District, Hangzhou, Zhejiang Province 311215, P. R. China

Address: 3rd Floor, Building T6, No. 308 Kangshan Road, Pudong District, Shanghai, 201315, P.R.China

Address: 11th Floor, No. 18 Zhihui Road, Huishan District, Wuxi, Jiangsu Province 214174, P. R. China